Advanced manufacturing institutes in the US

Back News

Economic growth is rooted in the interplay of five key elements: skilled labor, natural resources, capital formation, technological development, and geopolitical factors. While technology often relies on glamorous research or scientific progress, a sixth element – practical experience or “know-how” – can prove just as important. In fact, since 2000 alone, America has lost an alarming 5 million manufacturing jobs that have affected line workers, machinists, managers, and product designers, all facing potential skill loss due to this downturn.

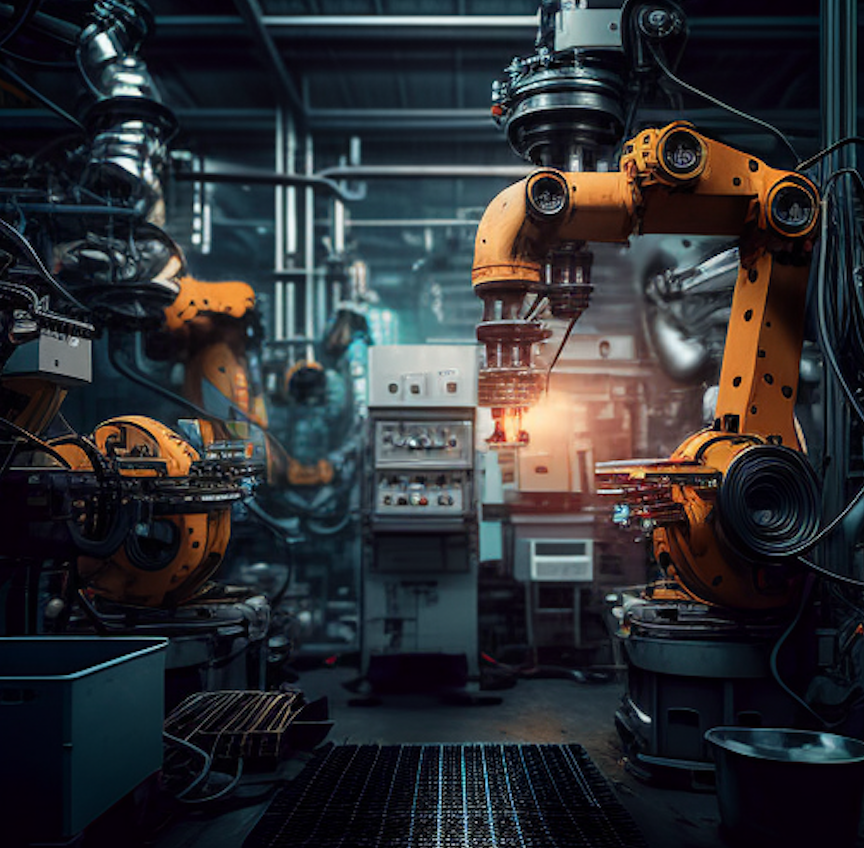

The advanced manufacturing institutes of the US have been at the forefront of creating new economic opportunities and bringing technology into the manufacturing field in the last decade. These institutes focus on creating a skilled workforce, advancing cutting-edge technologies, increasing productivity, and developing regional economic ecosystems. The 16 advanced manufacturing institutes nationwide specialize in various fields, ranging from robotics and 3D printing to composite materials, nanomaterials, and circuit integration. America Makes on developing additive manufacturing technologies for aerospace and defense applications. NextFlex is dedicated to creating flexible hybrid electronics for consumer and medical applications. The Digital Manufacturing & Cybersecurity Institute (MxD) is focused on advancing digital manufacturing technologies to help companies reduce costs and improve efficiency. Lightweight Innovations for Tomorrow (LIFT) aims to develop lightweight materials for the automotive and aerospace industries. PowerAmerica focuses on developing wide-bandgap semiconductor technology for power electronics. Rapid Advancement aims to improve energy efficiency through process intensification. Clean Energy Smart focuses on reducing energy usage through intelligent manufacturing practices. Advanced Robotics Manufacturing (ARM) Institute seeks to advance robotics technology for manufacturing. National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL) aims to accelerate biopharmaceutical innovation through advanced manufacturing techniques. Advanced Functional Fabrics of America (AFFOA) aims to develop advanced fabrics with unique properties such as sensing or energy generation capabilities. The Cybersecurity Manufacturing Innovation Institute (CyManII) focuses on developing and implementing cybersecurity solutions to protect the U.S. manufacturing industry from cyber threats. The Institute for Advanced Composites Manufacturing Innovation (IACMI) aims to accelerate the developing and adoption of advanced composite materials in various industries. The reducing EMbodied-energy And Decreasing Emissions (REMADE) initiative seeks to accomplish this by developing and deploying cutting-edge technologies and strategies that optimize manufacturing processes, reduce waste, and improve energy efficiency. American Institute for Manufacturing Integrated Photonics (AIM): Integrated Photonics (NNMI-IP) combines light-based communication systems with electronic circuits, enabling faster data transfer rates over longer distances than the traditional copper wire method. Manufacturing The Future Of bio-fabrication (BioFabUSA) focuses on creating functional tissues using fabrication techniques that can be used in regenerative medicine. Finally, the Bioindustrial Manufacturing and Design Ecosystem (BioMADE) aims to establish a sustainable and scalable bio-industrial manufacturing ecosystem by researching and developing advanced biomanufacturing technologies.

The last two decades have been hard for US manufacturing, but the nation is now determined to make a change. Over 16 advanced institutes are being established across America to spur economic growth and job creation while providing better products for consumers worldwide. To ensure these efforts are successful, additional investments must be made – including improved infrastructure and increased student training at elite universities. With such measures, the United States can expect more success in manufacturing than ever.